Products

Prefabricated steel frame 10 car parking space shade structure tent for sale

Five Advantages Of Products

- Germany imported PVDF membrane material

- 15 years life span

- 100% waterproof

- Strong self-cleaning ability

- H-shaped steel structure, easy installation

Product Details

This is a single cantilever steel structure parking shed. Its size is 30 * 6 * 2.3 meters, and it can park 10 cars. Every two pillars are used as a unit, the size of each unit is 6 * 6 * 2.3 meters, and two cars can be parked.

This parking shed is composed of German brand white PVDF membrane material and Q235 steel structure. PVDF film material has waterproof, sunshade, heat insulation, anti-ultraviolet, flame retardant, anti-wicking, anti-oxidation, and strong weather resistance. The steel structure adopts hot-dip galvanized anticorrosive treatment, which can prolong the service life of the steel pipe. In addition, we will add a layer of white paint, which is mainly used for decoration. It can also strengthen the anti-corrosion ability of steel pipes.

Application of parking shed

The parking shed can be used in living quarters, bus stations, airports, squares, schools, hospitals, restaurants and other places.

Installation of parking sheds

The installation of the membrane body includes four parts: expansion of the membrane body, connection and fixing, lifting in place, and tension forming.

Before unfolding the membrane, lay a temporary cloth on the platform to protect the membrane from damage and clean the membrane. Unfold the membrane in strict order. Before opening the package, you should proofread the marks on the package, confirm the installation location, and unfold it in the direction of the mark to avoid the unfolded membrane moving in the field. Wear soft-soled shoes when walking on the unfolded membrane surface. Do not wear hard objects to prevent the membrane body from being scratched.

After the membrane body is deployed on the platform, the membrane material and the cable are connected and fixed with a splint. The specifications of the plywood and the spacing between the plywoods should be installed in strict accordance with the design requirements. For the membrane body that is hoisted in place at one time, the clamp bolts and nuts must also be tightened in place at one time.

At present, cable-and-membrane structure hoisting is mostly applied by the multi-point overall lifting method, which is to transform the mature integrated "lifting" technology into the flexible structure construction of cable-and-membrane structure. This process requires that the entire process must be synchronized. During the lifting process, the lifting speed and distance of each lifting point are controlled to ensure uniform force transmission on the membrane surface.

It is also possible to adopt the method of block lifting to divide the membrane body into several working blocks according to the plane position. Each membrane body also adopts a multi-point overall lifting technology to hoist the whole place in place. If the overall lifting technology is adopted, more equipment and personnel are required to be invested, and the construction preparation period is longer. The whole membrane body is divided into 5 working blocks by block lifting method, the first and second sheets, the third and fourth sheets, the fifth and sixth sheets, the seventh and eighth sheets, and the ninth sheet. Sheet and the tenth sheet, 7 lifting points of the membrane body of each work block are simultaneously lifted. After all the membrane bodies have reached the design height, the superiority is quite obvious when they are connected together in the air. During the entire installation process, special attention should be paid to prevent the membrane body from generating excessive shaking under wind load.

Tension forming is an important part of the entire membrane structure construction. Whether the construction project can achieve results depends on whether the tension can meet the design requirements. When the support structure is a rigid boundary, the application of the prestressing force is carried out through a special structure. For flexible boundaries, the prestress can be adjusted by adjusting the position of the brace. In the tensioned cable membrane structure, the tensile prestress of the membrane is provided by the cables. The entire tensioning process is actually pulling various cables into place according to a predetermined stress. When tensioning, the order and magnitude of batch tensioning should be determined, the tensioning speed should be controlled, and the super tensioning value should be determined according to the characteristics of the material. The tensioning process can be the pre-stressing of the cable in batches and stages, and the tensioning can be gradually achieved to the design value. The overall tensioning can also be implemented. Construction records should be made for tension values with control requirements, and tensile travel records for those without control requirements.

Guangzhou Ruibo Membrane Structure Engineering Co., Ltd.

Contact Person: Mr.Antoni Pang

Department: Trade department

Post: Manager

Telephone: +8615777444557

Landline: +8615777444557

Company Address: No.1, Xiaolong Industrial Zone, Shiji Town, Panyu District, Guangzhou, Guangdong, China

Factory Address: No.1, Xiaolong Industrial Zone, Shiji Town, Panyu District, Guangzhou, Guangdong, China

Website: gzrmse.us764.com

Previous: Hot Sale Factory Price Waterproof...

-

Prefab Houses Calcium Silicate Board Wall Stretched Cable...

-

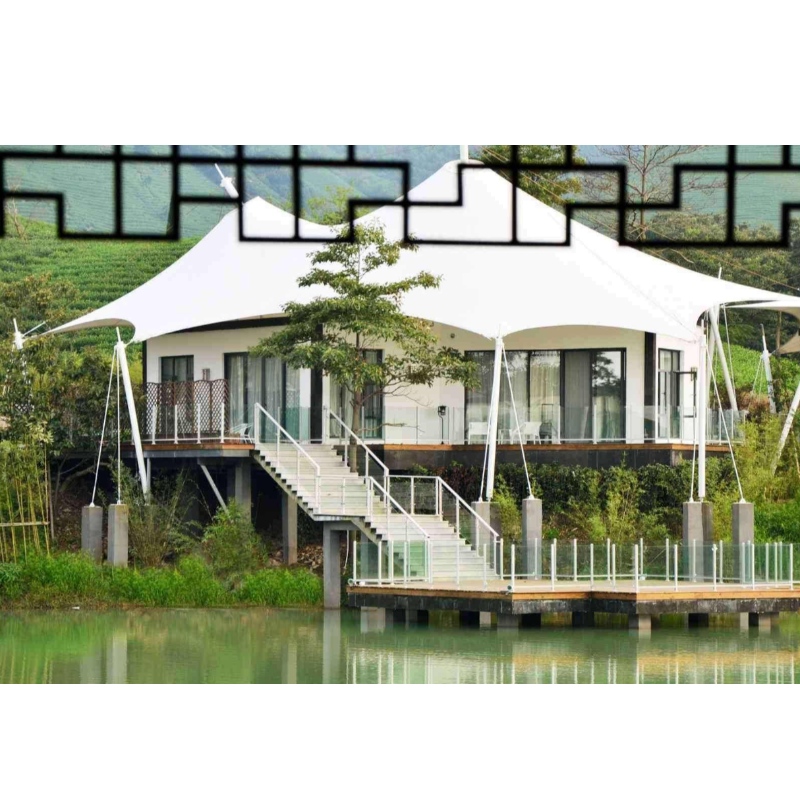

Outdoor Steel Frame Luxury Resort Tents With Hotel Anti -...

-

Prefab 2 Bedroom White PVDF Waterproof Fabriccalcium sili...

-

Prefabricated steel frame 10 car parking space shade stru...

-

Hot Sale Factory Price Waterproof PVC And Canvas Luxury S...

-

Prefab Easy To Install Big Size Metal PVDF Fabric Structu...

-

Prefab 2 Persons Houses China Glamping Luxury Tent Hotel ...

-

Prefab Outdoor Houses Cheap Glamping Tents Manufacturers ...